- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

Title: Double side adhesive labeling equipment with transparent label sensor

Key words: adhesive labeling equipment, sticker labeling equipment , adhesive labeling machine

Model: TB-751-2

Brand: FILL-PACK

Power: 3kw

Voltage: 220V 1PH 50HZ or customized

Driven force type: Electrical

Automation degree: Automatic

Application: Labeling

Application label: adhesive label/sticker/ adhesive sticker

Condition: New

PROPERTIES:

Capacity: 0-100 BPM or 0-20m/ s

Key material: SUS304

Fuction: adhesive labeling

Labeling head qty: 2

Labeling machine construction: linear

Suitable bottle shape: round/ square

Pressing bar: yes

Precision: +/- 1mm

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

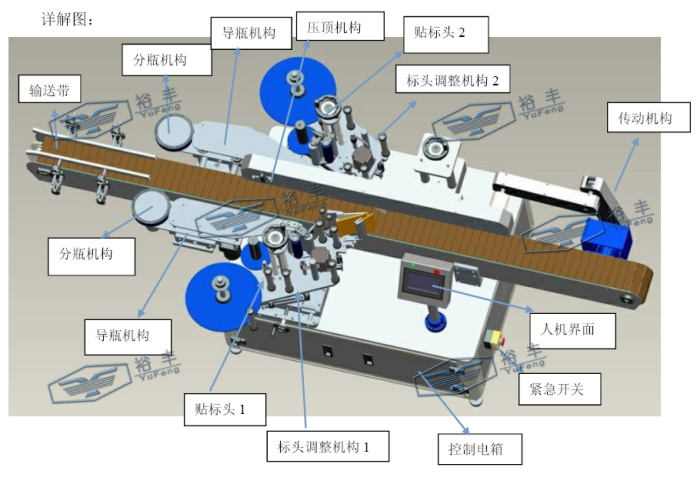

Double side adhesive labeling equipment with transparent label sensor

Function of adhesive labeling equipment:

Large touch screen, the operation is convenient, the parameter display be clear at a glance, truly realize the man-machine dialogue.

Adopt Taiwan Delta PLC control system,a more stable performance.

Adopt Japanese Keyence photoelectric sensor,higher sensitivity for checking object.

Adopt Italy Ever steppermotor for feeding label, Stable performance, labeling precision is high. With Italy Ever stepping motor drive, and Ever motor matching, signal never distortion

The horizontal, vertical, can adjust direction labeling position

Set up in your company existing transport, it also can use online.

No bottle,not feeding label.

Large control box, internal electric heat dissipation easier, detection is convenient, being increased

Stainless steel and aluminum alloy material.

Aluminum alloy surface by anodize painting, higher strength, good appearance.

Feeding label buffer device, Ensure that the process of tags do not be pulled apart or cause drag mark.

Main Configuration of adhesive labeling equipment:

N0. | Name | Model | Brand |

1 | PLC control system | DVP-14SS | DELTA (Taiwan) |

2 | Labeling Stepper motor | MT34FN46042M8-01 | EVER (Italy) |

3 | Labeling Stepper motor driver | LW806 | EVER (Italy) |

4 | Frequency changers | VFD007M21A-A | DELTA (Taiwan) |

5 | Labeling sensor | FS-V11 | Keyence (Japanese) |

6 | Label detecting sensor | / | Leuze (Germany) |

7 | Touches screen 7INCH | PWS5600S-S | HITECH (Taiwan) |

8 | Conveyor Motor | RV50-30-0.55FA-DZ-ZA-b06 | VTV |

9 | Adjusting motor | 5RK90RGU-CF/5RK-15-K | VTV |

10 | Bottle devision motor | 5RK90RGU-CF/5RK-30-K | VTV |

11 | Bearings | / | Japan NSK |

12 | Stainless steel material | / | 304SS |

13 | Aluminium alloy | / | Surface anode gush arenaceous technology |

Adhesive labeling equipment constructional design:

1, It is a must to pack the adhesive labeling equipment well with wooden case since there is no frame to protect the precise elctronics.

2, 10-15 working days to produce the adhesive labeling equipment as clients’ samples provision for a quick delivery.

WHY CHOOSE US?

1.We are China Leading Packing Machines Manufacturer.

2.Alibaba Assessed Gold Supplier.

3.We give our Trade Assurance for customers.

4.Inspected by the Inspection Institution of SGS Certification.

5.100% QC inspection Before Shipment.

6.Best Quality & Best Service with Competitive price.

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: