- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

Title: 3 stage PID control plate sterilizer to produce 1000 liter juice per hour

Key words: plate sterilizer, juice sterilizer, plate pasteurizer

Model: PS-1000

Brand: FILL-PACK

Power: 3.6kw

Voltage: 380V 3PH 50HZ or customized

Driven force type: Electrical

Automation degree: automatic

Application: juice sterilization

Condition: New

PROPERTIES:

Volume: 1000L

Key material: SUS304

Fuction: juice sterilization

Sterilization way: steam heating

Working pressure: 0.4Mpa

Power: 3.6Kw

Steam consumption: 0.05kg/L

Plate capacity: 16m2

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

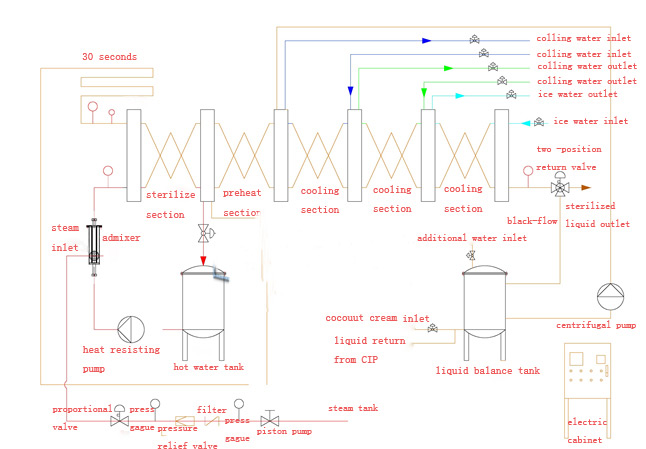

1. The plate sterilizer is an once integrated sterilizing equipment which is used to heat、sterilize、warm and cool heat-sensitive liquid such as fresh milk、juice beverage and wine. It can make the materials to prolong the quality guarantee time through sterilization and cooling.

2. Adopt the treating methods of the ultra high temperature:

It can make the liquid milk, tea drink and juice to reach a strict sterilization, then transfer it to aseptic package. The sterilizing temperature is 80-137℃ and the warming time is 3-5s.The machine could keep the original color and flavor of the beverage and dairy product as much as possible. The guarantee time can reach 6 to 12 months.

3. The equipment has the features of high recovery rate, compact structure, beautiful appearance and easy safe temperature control. The liquid through the sterilization of the machine can be used to hot filling and cold filling. The temperature of the outlet materials can be controlled automatically. The equipment has two modes of PLC control type and semi-automatic type. It also has safety protection measurement, alarm for high temperature and function of low temperature reflow. It can make various assembly designs.

4. Main configuration of equipment: material pump, balancing tank, hot water system, temperature controller and recording meter, electrical control system.

Working principle chart:

The plate sterilizer will be wrapped well by PE film for surface protection and motor will be wrapped for waterproof

Wooden case will be covered then for long distance delivery

1, Pre-quotation communication to know customers’ excat requirement and give proper suggested frame;

2, Quotation offer as in advance communications;

3, Quotation explanations given if necessary;

4, Plant design and bottle-cap-label searching & design if needed after offer confirmed;

5, Contract signing basing on all discussed;

6, Production as contract items;

7, Inspection and delivery done as contract standard;

8, Technician service overseas as contarct agreed;

9, Whole life after sales service for spare parts;

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: