- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

Title: SUS 304 beverage blending system to produce 3T/h granule juice

Key words: beverage blending system, drink processing system, beverage processing system

Model: TPX-3000

Brand: FILL-PACK

Power: 15kw

Voltage: 380V 3PH 50HZ or customized

Driven force type: Electrical

Automation degree: Automatic

Application: Granule Beverage

Processing steps: mixing - filteration - sterilization - smoothing - filling

Condition: New

PROPERTIES:

Capacity: 3 T /h

Key material: SUS304 or 316L

Fuction: beverage processing

Processing liquid: granule beverage

Sterilization temprature: 105-125℃

Filling type: granule filling

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

1.Sugar melting pot for beverage blending system

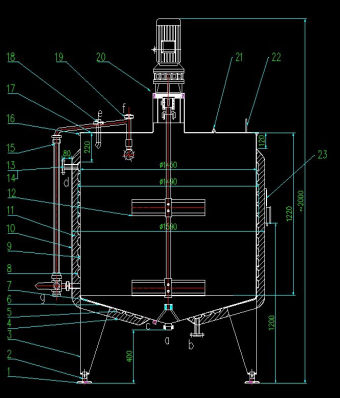

2, Mixing tank for beverage blending system

2.1, quick open manhole,

2.2, anti foaming liquid inlet,

2.3, CIP cleaning head,

2.4, dust proof respirator,

2.5, glass lever gauge

2.6, sampling valve

2.7, anti rotational flow outlet

2.8, low liquid lever sensor

2.9, stand

3, Double filter for beverage blending system

Model No:SL-1

Capacity:1-2T/h

Filter area:0.15m2

Precision: 120um

Working pressure:0.2Mpa

Inlet/outlet:DN38

Dimension:800*350*800mm

4, Homogenizer for beverage blending system

Working pressure:25MPa

Capacity: 3000L/H

Power: 22KW

Inlet: 25mm

Outlet: 15mm

Viscosity: ≤0.2

Temperature: ≤80℃

Motor speed: 1440 rpm

Weight: 1300kg

Overall dimension: 1600*1100*1550mm

1, We will mark each pipe and valve when disassembling for the beverage blending system before delivery for client’s easy set up at local

2, The marked pipes and valves will be arranged in order and packed well

3, The tanks will be wrapped well by PE film for surface protection and motor will be wrapped for waterproof

1,Pre-quotation communication to know customers’ excat requirement and give proper suggested frame;

2, Quotation offer as in advance communications;

3, Quotation explanations given if necessary;

4,Plant design and bottle-cap-label searching & design if needed after offer confirmed;

5,Contract signing basing on all discussed;

6,Production as contract items;

7,Inspection and delivery done as contract standard;

8,Technician service overseas as contarct agreed;

9,Whole life after sales service for spare parts;

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: