- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

Title: Linear can filling line for 5133 tin plate can with 206 end

Key words: can filling line, can filling machine, juice canning line

QUICK DETAILS:

Model: XG-1 FG-12 FBZ-1

Brand: FILL-PACK

Power: 3kw

Voltage: 380V 3PH 50HZ or customized

Driven force type: Electrical

Automation degree: Automatic

Dimension: 7500*1200*2000mm

Weight: 2 ton

Application: juice

Packing category: Can

Packing material: tin plate

Condition: New

PROPERTIES:

Capacity: 0-2000 BPH (0.5L)

Applicable bottle size: 0-0.5L

Key material: SUS304

Fuction: can filling

Processing liquid: juice

Filling precision: +/- 1mm

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

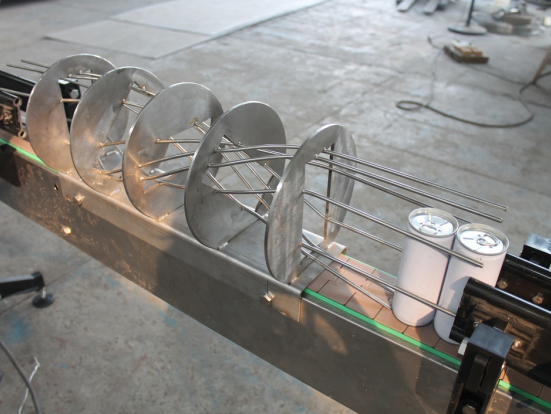

Cans will go to the can sealing machine through conveyor. The 6 station dia plate will turn the cans under lid loading head , the lid will be loaded on can mouth automatically with the can body triggering. With the motor driven energy, the can which already be loaded with lid will go forward to sealing position. With the lifting cam, the sealing head can go up and down when cans come and go. The sealing head will go down to press on the can when the cans come; The sealing head are composed with 4 groups of sealing wheels around one circle, the 4 groups of wheels will turn rapidly together with sealing head in the same direction to process sealing job. The whole system will finish edge rolling job.

The sealing wheels are in 2 step sealing model to make sure the the can edge and lid edge close tightly. Then the sealed can will be suitable for all kinds of liquid, no leakage.

The machine adopts drehstrom asynchronous motor Y802-4 at 1390r/min, with deceleration by triangle belt pulley and turbine, the speed changes to 40r/min.Whole machine is made by SUS304.

Characters:

1, Ingenious lid loading device to make sure no can, no lid loading, no sealing;

2, Energy saving model, one motor can process all actions;

3, Full sealing effect make sure to be suitable for liquid packing can;

4, The machine suitable for all kinds of cans with same diameter, height can be adjusted easily;

5, Compact construction, only need small space to use the machine;

6, Delivered with whole machine, no need commissioning again after delivery;

Parameters:

Capacity: max 2000BPH

Power: 0.75KW

Dimension: 950*700*1900mm

Weight: 500KG

Sea worthy packing for can filling machine

25 working days after can samples received

1, Pre-quotation communication to know customers’ excat requirement and give proper suggested frame;

2, Quotation offer as in advance communications;

3, Quotation explanations given if necessary;

4, Plant design and bottle-cap-label searching & design if needed after offer confirmed;

5, Contract signing basing on all discussed;

6, Production as contract items;

7, Inspection and delivery done as contract standard;

8, Technician service overseas as contarct agreed;

9, Whole life after sales service for spare parts;

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: