- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

Title: BCGF18-18-6 Monoblock beer filling machine with de-foaming unit

Key words: beer filling machine , beer bottling line,beer filling line

QUICK DETAILS:

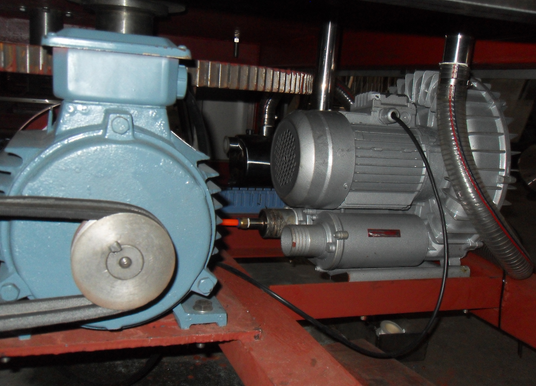

Model: BCGF18-18-6

Brand: FILL-PACK

Main motor Power: 2.2kw

Voltage: 380V 3PH 50HZ or customized

Driven force type: Electrical

Automation degree: Automatic

Dimension: 2630*1850*2500mm

Weight: 5000kg

Application: beer

Packing category: Bottles

Packing material: glass

Condition: New

PROPERTIES:

Capacity: 0-3000 BPH (0.5L)

Applicable bottle size: 0-1.5L

Key material: SUS304

Fuction: beer filling

Processing liquid: beer

Filling precision: +/- 2mm

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

1) Balance filling method for beer filling machine

2) Filling machine with spring-type mechanical lifting equipment to upgrade glass bottles, large bearing support floundering in the vat and use of guide-rod in the orientation of the structure, there are pre-cover features.

3) Long-tube filling valves are adopted, with CO2 fully exchanging with air inside glass bottles, to decrease the rinsing of oxygen effectively. with cylinder liquid level and the back pressure controlled by a variable signal proportional. Fast, stable, accurate, to be vacuum one at a time.

4) High-pressure foam stimulator is equipped to minimize air remaining at the neck.

5) Centralized automatic lubrication system, simple for maintenance.

6) Before capping system , we have jetting system to remove the beer foam on the top of bottle mouth to be sure the Oxygen content less than r0.15 mg O2/l

7) Filling level tolerances : ± 2.0 mm

8) Bottle break rate : max. 0.01% (1:10,000)

9) Filling machines includes broken bottle automatically stopping valve, broken bottle washing, and foam automatically exhausting device.

10) With perfect CIP cleaning function, and capable of rinsing filling pipes with acid, lye liquid and hot water.

11) All the materials in contact with the valves, tanks, pipes are made of stainless steel 304 materials, inside and outside the wall of mirror-polished, ensuring it is healthy.

12) Manually dry oil lubrication system to make sure equipment maintenance is more convenient.

Sea worthy packing for beer filling machine

35 working days after bottle samples received

1, Pre-quotation communication to know customers’ excat requirement and give proper suggested frame;

2, Quotation offer as in advance communications;

3, Quotation explanations given if necessary;

4, Plant design and bottle-cap-label searching & design if needed after offer confirmed;

5, Contract signing basing on all discussed;

6, Production as contract items;

7, Inspection and delivery done as contract standard;

8, Technician service overseas as contarct agreed;

9, Whole life after sales service for spare parts;

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: