- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

Title: SUS316 1000L tank CIP cleaner with view ladder

Key words: CIP cleaner, CIP machine, CIP

Model: CIP-1000*3

Brand: FILL-PACK

Power: 3kw

Voltage: 380V 3PH 50HZ or customized

Driven force type: Electrical

Automation degree: automatic

Application: CIP cleaning for machine

Condition: New

PROPERTIES:

Capacity: 1000L

Key material: SUS316

Fuction: CIP cleaning

Cleaning liquid: acid, alkali, hot water, clean water

Cleaning time: 15-25 mins per cycle

Heating way: steam heating

Cleaning steps: 5

Tank construction: with insulation layer

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

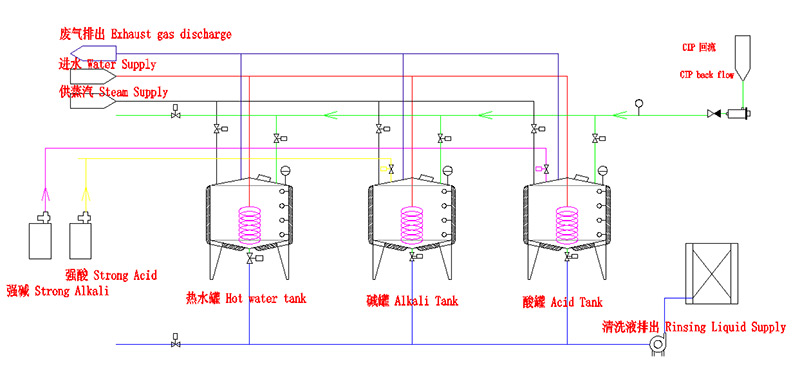

The CIP cleaner includes separate alkali and acid tank and water tank with steam heating coil pipes inside;

Centrifugal pump to discharge cleaning liquid to the machines which need to be washed;

Feedback pump can be added for cleaning liquid recycling;

Ladder easier for status checking inside the tanks;

Hot water tank | Acid tank | Alkali tank | |

Volume | 1000L | 1000L | 1000L |

Material | Inner SUS304-2mm | Inner SUS316-2mm | Inner SUS316-2mm |

Construction | full closed, cylinder body, cone top, cone bottom | ||

Power | 2.2KW | ||

Strong acid tank | PE 50L | ||

Strong alkali tank | PE 50L | ||

CIP cleaner constructional design:

Sea shipping worthy packing will be applied;

25 working days leading time for delivery after order confirmed

1, Pre-quotation communication to know customers’ excat requirement and give proper suggested frame;

2, Quotation offer as in advance communications;

3, Quotation explanations given if necessary;

4, Plant design and bottle-cap-label searching & design if needed after offer confirmed;

5, Contract signing basing on all discussed;

6, Production as contract items;

7, Inspection and delivery done as contract standard;

8, Technician service overseas as contarct agreed;

9, Whole life after sales service for spare parts;

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: